Axial angular contact ball bearings ZKLDF

Structure

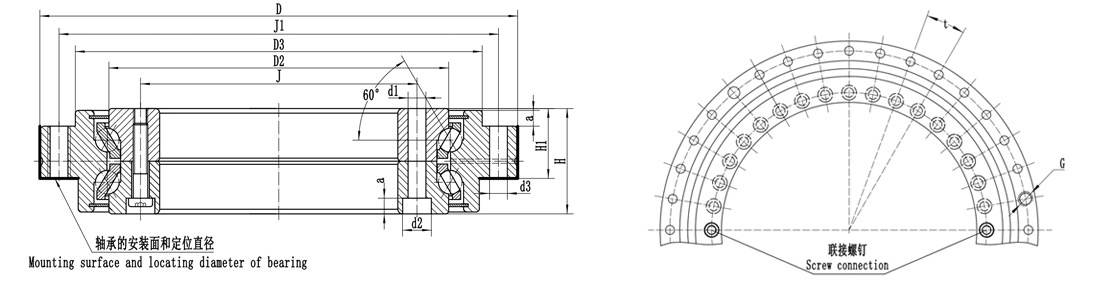

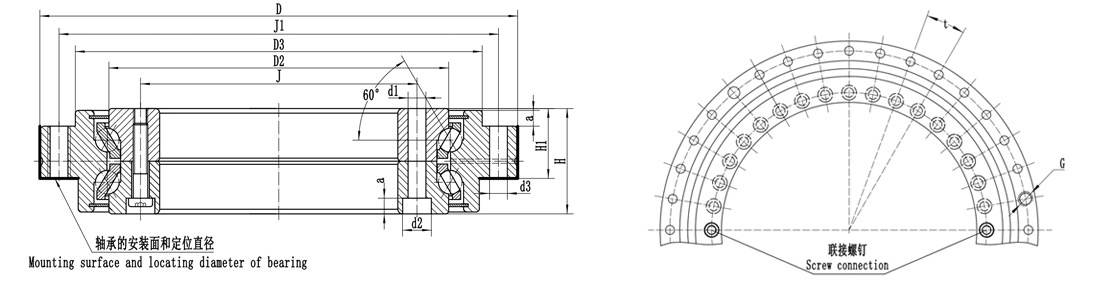

Axial angular contact ball bearings ZKLDF comprise a single-piece outer ring, a two-piece inner ring and two ball and cage assemblies with a contact angle of 60°. The outer ring and inner ring have fixing holes for screw mounting of the bearing on the adjacent construction.

The unit is located by means of retaining screws for transport and safe handling.

Sealing

Axial angular contact ball bearings have sealing shields on both sides.

The initial axial angular contact ball bearing is greased before disptach,The bearings can be relubricated via the outer ring.

Operating temperature

Axial/radial bearings and axial angular contact ball bearings are suitable for operating temperatures from –30 °C to +120 °C.

FeaturesAxial angular contact ball bearings ZKLDF are low-friction,ready-to-fit, pregreased bearing units with high accuracy for very high speeds, high axial and radial loads and high demands on tilting rigidity.

Application

Axial angular contact ball bearings are particularly suitable for precision applications involving combined loads. Their preferred areas of use are bearing arrangements in rotary tables with a main spindle function, for example in combined milling and turning, as well as in milling, grinding and honing heads and in measurement and testing equipment.

Custom made

Custome made available ,material materials ,dimensions etc.

ZKLDF with features of low-friction,high accurancy , high limit rotate speed etc.can bear higher axial load,radial load and with higher tilting rigidity. This kind of bearings are especially suitable for precision machine tool rotary table,honing heads and measuring testing equipments which bear composite load.

| Bearing type | Boundary dimensions | The fixing holes | Number of retaining screws | Extraction thread hole | Number of pitches X angle of pitches MA | Screw tightening torque MA |

Basic load rating | Limiting speed | Bearing frictional torque | Weight | |||||||||||||||

| Inner ring | Outer ring | ||||||||||||||||||||||||

| axial | |||||||||||||||||||||||||

| d | D | H | H1 | D1 | D2 | D3 | J | J1 | d1 | d2 | a | QTY | d3 | QTY | dynamic load | static load | |||||||||

| Grease | |||||||||||||||||||||||||

| unit:mm | unit:mm | unit:mm | G | QTY | QTY X t | MA | Ca | Coa | Nm | Kg | |||||||||||||||

| KN | r/min | ||||||||||||||||||||||||

| ZKLDF100 | 100 | 185 | 38 | 25 | 160 | 136 | 158 | 112 | 170 | 5.6 | 10 | 5.4 | 16 | 5.6 | 15 | 2 | M5 | 3 | 18×20° | 8.5 | 67 | 251 | 2800 | 1.6 | 4.5 |

| ZKLDF120 | 120 | 210 | 40 | 26 | 184 | 159 | 181 | 135 | 195 | 7 | 11 | 6.2 | 22 | 7 | 21 | 2 | M8 | 3 | 24×15° | 14 | 72 | 315 | 2400 | 2 | 6 |

| ZKLDF150 | 150 | 240 | 40 | 26 | 214 | 188 | 211 | 165 | 225 | 7 | 11 | 6.2 | 34 | 7 | 33 | 2 | M8 | 3 | 36×10° | 14 | 76 | 365 | 2000 | 3 | 7.5 |

| ZKLDF180 | 180 | 280 | 43 | 29 | 244 | 221 | 241 | 194 | 260 | 7 | 11 | 6.2 | 46 | 7 | 45 | 2 | M8 | 3 | 48×7.5° | 14 | 85 | 440 | 1700 | 3 | 8 |

| ZKLDF200 | 200 | 300 | 45 | 30 | 274 | 243 | 271 | 215 | 285 | 7 | 11 | 6.2 | 46 | 7 | 45 | 2 | M8 | 3 | 48×7.5° | 14 | 112 | 550 | 1600 | 4.5 | 11 |

| ZKLDF260 | 260 | 385 | 55 | 36.5 | 345 | 313 | 348 | 280 | 365 | 9.3 | 15 | 8.2 | 34 | 9.3 | 33 | 2 | M12 | 3 | 36×10° | 34 | 155 | 920 | 1200 | 7.5 | 22 |

| ZKLDF325 | 325 | 450 | 60 | 40 | 415 | 380 | 413 | 342 | 430 | 9.3 | 15 | 8.2 | 34 | 9.3 | 33 | 2 | M12 | 3 | 36×10° | 34 | 165 | 1110 | 1000 | 11 | 28 |

| ZKLDF395 | 395 | 525 | 65 | 42.5 | 486 | 450 | 488 | 415 | 505 | 9.3 | 15 | 8.2 | 46 | 9.3 | 45 | 2 | M12 | 3 | 48×7.5° | 34 | 214 | 1470 | 800 | 16 | 39 |

| ZKLDF460 | 460 | 600 | 70 | 46 | 560 | 520 | 563 | 482 | 580 | 9.3 | 15 | 8.2 | 46 | 9.3 | 45 | 2 | M12 | 3 | 48×7.5° | 34 | 255 | 1860 | 700 | 21 | 50 |

| ZKLDF580 | 580 | 750 | 90 | 60 | 702 | 656 | 700 | 610 | 720 | 11.4 | 18 | 11 | 45 | 11.4 | 42 | 3 | M12 | 6 | 48×7.5° | 68 | 282 | 2150 | 500 | 40 | 82 |

| ZKLDF650 | 650 | 870 | 122 | 78 | 800 | 739 | 802 | 680 | 830 | 14 | 20 | 13 | 45 | 14 | 42 | 3 | M12 | 6 | 48×7.5° | 116 | 388 | 2350 | 440 | 63 | 168 |

Consultation

Consultation